An aircraft towing bar is a heavy-duty tool used to connect an aircraft to a towing vehicle, allowing the aircraft to be moved easily and safely on the ground. It acts as a link between the aircraft's nose gear or main wheels and the tow vehicle, facilitating precise movements and positioning of the aircraft.

Durable Construction: Aircraft towing bars are constructed from high-strength materials such as steel or aluminum to withstand the considerable forces involved in towing aircraft. This durability ensures long-term reliability and safety.

Adjustable Length: Many towing bars are adjustable, allowing them to accommodate various aircraft sizes and types. This feature enhances versatility and makes it easier to use the same equipment across different aircraft models.

Compatibility: Towing bars are designed to be compatible with specific aircraft types and towing vehicles. This ensures a secure connection and optimal performance during towing operations.

Safety Mechanisms: Advanced towing bars come equipped with safety features such as locking pins and hydraulic systems to prevent accidental disengagement and ensure stable operation during towing.

Ease of Use: The design of towing bars often includes user-friendly features such as ergonomic handles and quick-connect mechanisms, making them easier to operate and maneuver.

Product Description

Detailed Image of Universal Aircraft Towing Bar for A330,A340, A350, B757,B767,B777

Safety Mechanisms of Universal Aircraft Towing Bar for A330,A340, A350, B757,B767,B777

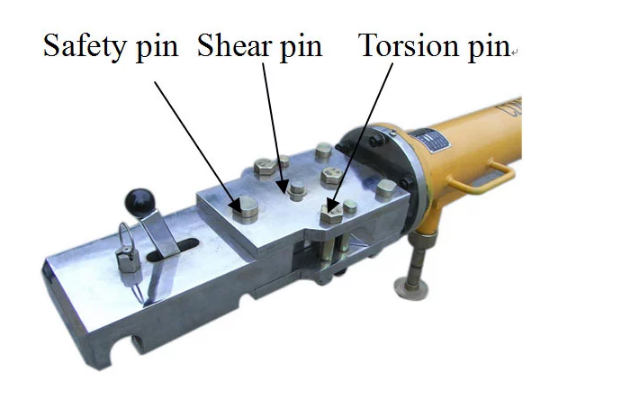

The traction head part:

this part is used for connecting landing gear and tow bar body,

Shear pin, torsion pin and safety pin are fixed on the traction head.

Shear pin:

To prevent excessive force of shaft pushing/towing rod and damaging the aircraft.

Torsion pin:

To prevents a larger angle when pushing / pulling the aircraft and causes excessive axial force to damage the aircraft.

Safety pin:

To prevent the impact of the shear pin and torsion pin after breaking, the damage will be too large and damage the aircraft.

Copyright © 2025 Tianchang Cheers Metal Limited. | All Rights Reserved

We are here to help you! If you close the chatbox, you will automatically receive a response from us via email. Please be sure to leave your contact details so that we can better assist